04/03/2021

A constantly changing market environment, Covid 19 and co.: Companies in the manufacturing industry are facing numerous challenges. In this viewpoint interview, Dr. Stephan Melzer and Stefan Klinge from the Automotive division of the msg group talk about collaboration, technical trends and why companies should not always chase the next hype.

Mr. Melzer, Mr. Klinge, which particular challenges is the manufacturing industry facing this year?

Stephan Melzer: The challenges are many and unfortunately overlap at present. First and foremost, there is the Covid 19 situation with its economic impact. However, international business, which is characterized by Brexit and the trade tensions between China and the United States, among other things, is also presenting companies with significant challenges.

Stefan Klinge: In addition, of course, it is the wave of digitalization that will continue to drive and challenge the manufacturing industry. This is especially challenging for medium-sized companies. More than ever, it is important to be efficient and flexible at the same time. And if you are looking for practical solutions to this very ambidexterity, msg is the ideal partner.

Because you have mastered this balancing act?

Stephan Melzer: Of course, there is no one-fits-all solution. But we offer exactly this kind of differentiated consulting, solutions and services for digital twins and decarbonization, Companies have to keep all four dimensions in sight: People, organization, technology and also business purpose. They must not forget that these are all interdependent. But, in my view, anyone that focuses on just one dimension is making a mistake. This is the greatest risk of malinvestments.

left: Dr. Stephan Melzer / right: Stefan Klinge

Let's talk about product development. What are the challenges here?

Stefan Klinge: When we talk about product development, a key issue is collaboration and thus the task of protecting intellectual property. This requires good solutions for data sovereignty and IT security.

Stephan Melzer: What is equally important is that the approach of engineers is changing and that they have to position themselves more broadly in the future. One example from the area of user-centric design: You can think about a lot of things in the design process, but then users come along and use the product in a completely different way. In short, the principle of design follows user also applies to engineering processes. It is crucial to intensively address the customer and their needs. This does not necessarily have to be done in advance, but can also be a learning process that emerges from use. In a nutshell: Learning from user behavior.

In your view, which technical trends for companies are emerging?

Stefan Klinge: If we only focus on technology, there are three main aspects: First, process automation through artificial intelligence (AI) or robotic process automation (RPA) - in other words, streamlining in general. Corona shows us very clearly what is possible at critical moments. Secondly, the digital twin or, in a first step, a “digital shadow” (process data that the machines generate during operation), which is then the input data for process automation. In addition, data sovereignty and mastery of data security will play a central role in the future. They help to establish data-driven interfaces to companies within the supply chain. Those who finally implement these trends will be best placed to address the issue of decarbonization.

What does this actually mean for product development?

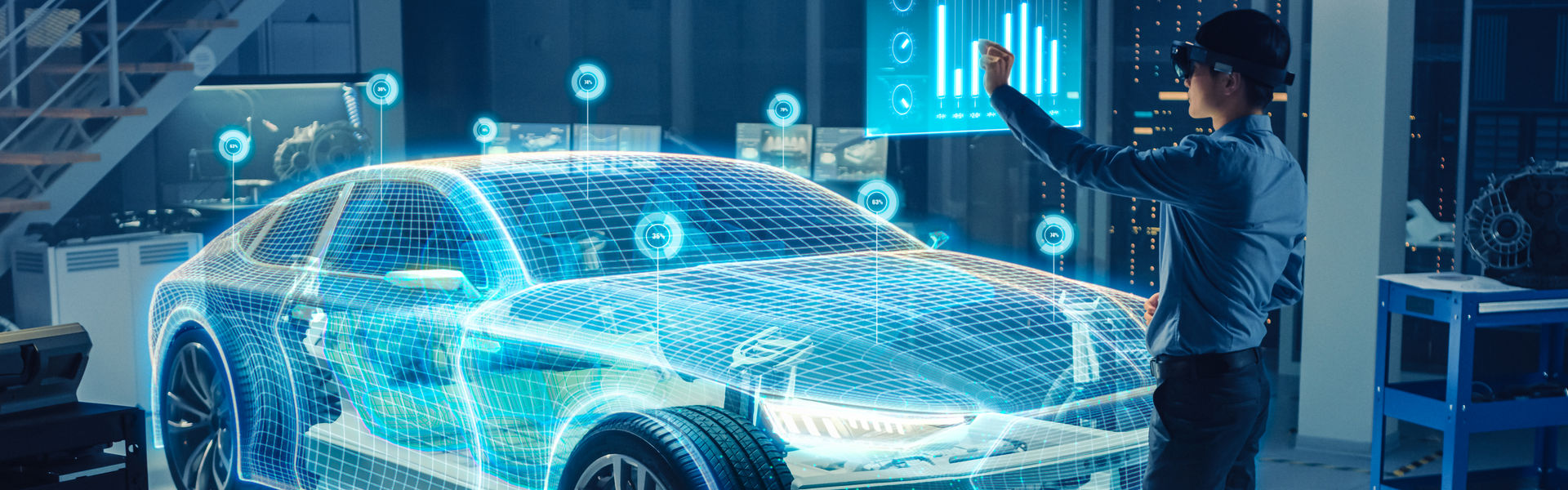

Stephan Melzer: First of all, that there is still a need for consistent digitalization of processes. Those who visualize early on in research and development (3D, augmented reality and virtual reality), for example, avoid rework and thus reduce costs. It is not primarily about chasing the next hype, but rather correctly using or further developing the procedures and technologies that are already known.

You already touched on the topic of digital twins. What do such trends (technologies) - including big data - mean for engineers?

Stefan Klinge: The digital twin of a product and production is the basis for many aspects of digitalization. If you cannot appropriately format data from production machines, you cannot use AI at a later stage. And those who think that artificial neural networks can simply create intelligence from data are wrong. A toddler using Google will certainly not discover any new astronomical theories.

Stephan Melzer: With Industry 4.0 (I4.0) and the Internet of Things (IoT), digital shadows are fast developing into large data volumes. But that doesn't yet make for big data. Big data only becomes interesting when I connect unstructured data from different domains. The manufacturing B2B industry faces the problem here that it is has little access to usage data because most B2C companies are not willing to part with it. Thus, mostly only the data from their own supply chains (currencies, production data, etc.) is left for the purpose of connecting. The core of data usage therefore resides in the digital twin - which allows structured data to be built up - as well as in sovereign data exchange: key word GAIA-X. The overarching goal of the automotive industry, for example, is to comprehensively network supply chains.

What are other engineering obstacles in automotive companies?

Stephan Melzer: As already mentioned, one important issue for companies is of course to reduce their CO2 footprint. Here, however, various areas always have to be taken into account - from the supply chains and the use of certain energy sources to the use of material in production and logistics. Numerous industries and services within this event chain are already customers of the msg group. Thus, besides us, there are not many IT service providers that can offer similar comprehensive consulting services in this area. We have combined the knowledge of decarbonization in our msg group companies m3 management consulting (Utilities), msg industry advisors (Supply Chain, Chemicals) and msg systems (Logistics, Food, Automotive) in such a way that we can help our customers wherever they need us.