Digital twin

Key to homologation in highly automated driving

Digital twin: Key to homologation in highly automated driving

In the digital transformation, the vision of the digital twin determines the way in which information will be used across fields or companies in the future. Many companies are taking a close look at the digital twin, but generally do not exploit its full potential. This also applies to the required test procedures as part of homologation.

Before a car can be built and sold in Germany, the Federal Motor Transport Authority (Kraftfahrtbundesamt) must approve the new vehicle models and functions. This means that the OEM must test the vehicle functions and parts relevant to certification in advance and have them confirmed by the Federal Motor Transport Authority. This process is known as homologation.

In the article on vehicle software identification using RxSWIN for vehicle homologation, Eva Hauth, Senior Business Consultant at msg, explains how type approval is moving more and more toward electronics and software as vehicles continue to evolve with the increasing number of ECUs. The trend here is toward centralization on a few intelligent ECUs in a vehicle. For this reason, the software used in a vehicle is now to be given greater consideration in the context of type testing and approval. Within the framework of a UNECE certification of the software update management system, this is implemented, among other things, with the aid of regulation-related software identification numbers, the RxSWINs (Regulation x Software Identification Number).

The testing and approval of automated or semi-autonomous driving functions represent a new challenge in homologation. Vehicle customers and authorities expect these new technologies to be thoroughly tested to ensure safety for passengers as well as for the environment. The increasing number of communication interfaces adds issues such as cybersecurity and data protection, which also need to be reviewed and ensured. To enable homologation for automated driving, new test methods and corresponding regulations must be established. The new test methods must combine physical real-world tests with scenario-based virtual simulations.

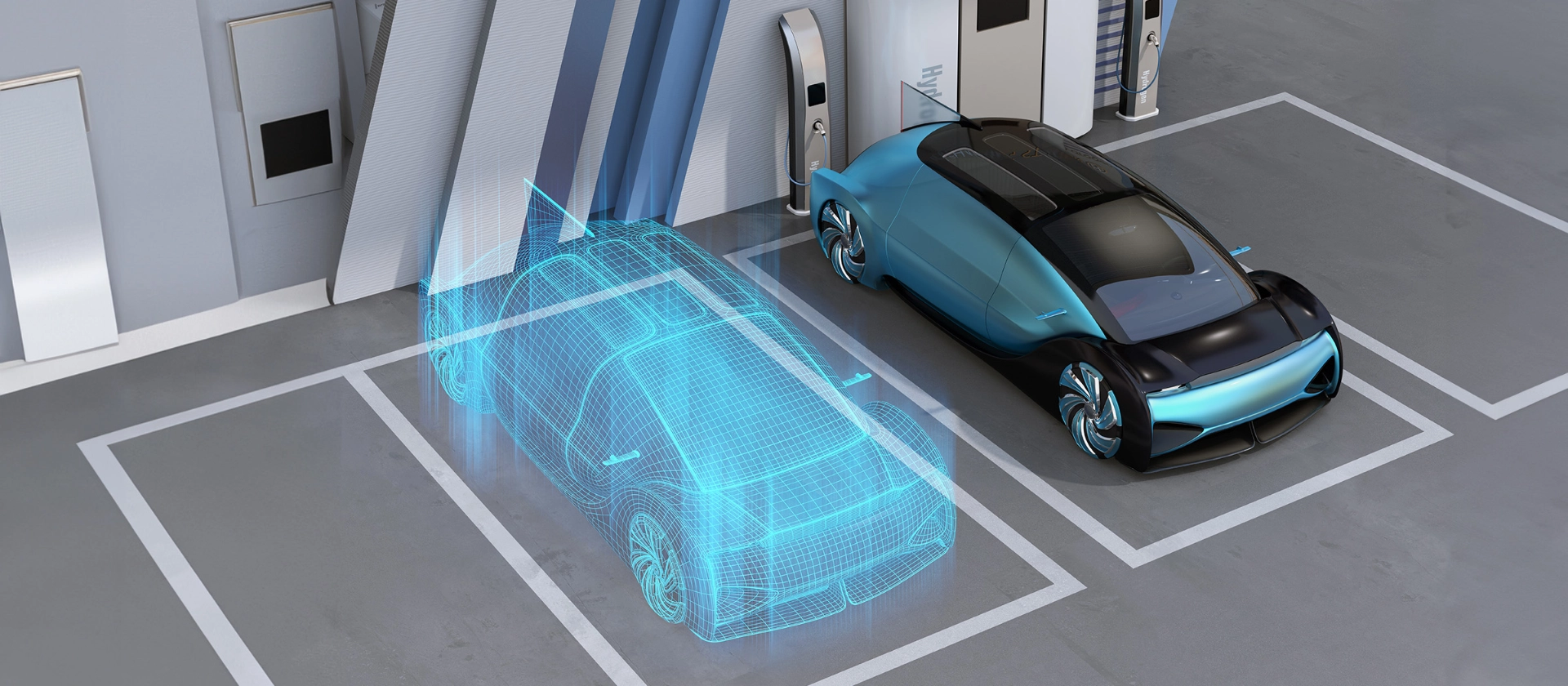

This is where the digital twin can lay the groundwork for homologation.

According to estimates in a study by Prof. Hermann Winner, a vehicle technology expert from Darmstadt, around 6.6 billion test kilometers are needed before highly automated driving functions can be homologated safely and reliably. This does not appear to be feasible in practice, either in terms of time or commercially. This can only be accomplished by IT-supported simulation of driving situations. On the one hand, the highly automated driving function is mapped as a digital twin. On the other hand, a virtual test field based on reality is set up. This allows the driving function to be validated and secured in a virtual test environment. This is referred to as systems-of-systems. In our view, the challenge here lies not in the technology, but in the development of procedures for the homologation of highly automated driving functions and in social acceptance.

But what actually characterizes a digital twin? It is an exact digital 1:1 representation of a real product, a production facility or a process. A complete digital twin requires a digital master (TARGET state) and a digital shadow (ACTUAL state). A sensor system captures and controls the data and its transfer to the virtual world. The processing of the data by business analytics or artificial intelligence can take place in the real world, for example in the vehicle, but primarily happens in the digital twin.

Together with our customers, we develop a vision and a target image of the digital twin with a focus on the benefits and a business case of the respective use case. To ensure the benefits, we perform, for example, data flow analyses along the lifecycle and check the data availability and quality. A proof of concept (PoC) can help provide transparency about the benefits. Primarily, the PoC validates concepts to ensure that the data provides meaningful insights. The challenge lies in the implementation of digital twin concepts, as holistic approaches here entail high complexity and overlapping interfaces. A hybrid model of conceptual design and agile implementation has proven itself in the implementation, which on the one hand focuses on the planned benefit and target image and on the other hand offers enough flexibility to readjust the concept iteratively.

Our experts bring extensive IT and industry expertise to the digital twin, both functionally and technically. With our industry and methodological expertise, we have been successfully doing projects for many years. In the area of homologation, we support our customers in identifying relevant regulations, evaluating company-specific processes and homologation procedures through to obtaining type approval. From exploration and proof-of-concept to implementation and operation, we offer qualified services and solutions (end-to-end) from a single source.

- Quickly determine where you stand with the Digital Twin Readiness Assessment

- Solid experience in the manufacturing industry

- Independent system integrator for digital twins from concept to implementation

- Comprehensive technology and cloud competences for the implementation of digital twins

- Active participation in GAIA-X to define the digital twin use case.